Plant Automation Tamworth

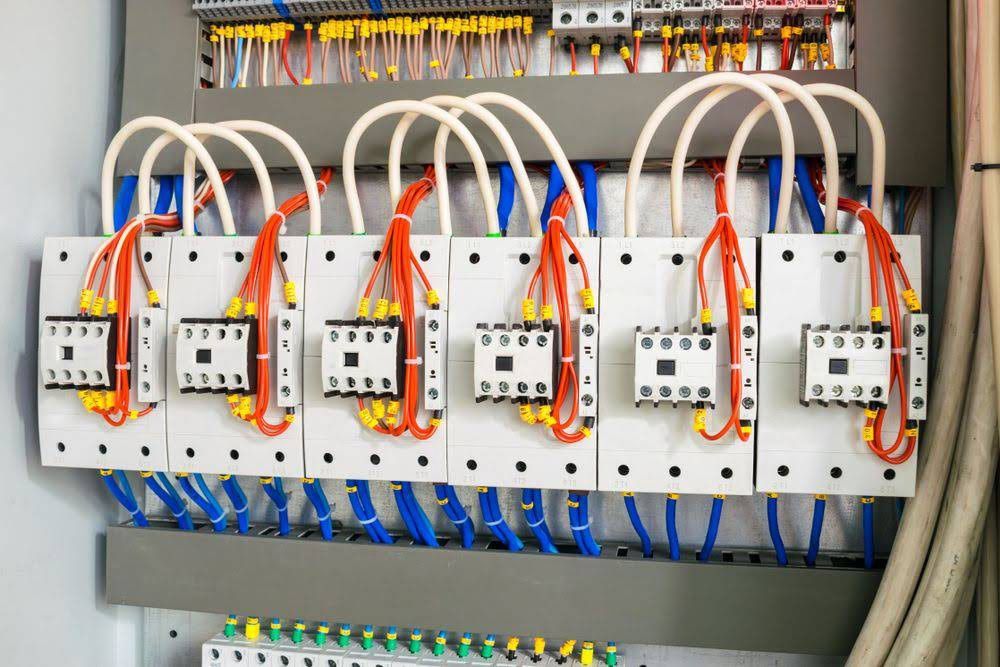

Industrial Automation Services

As experts in plant automation and control systems, A & J Electrical Contractors in Tamworth works across a range of industries including manufacturing and food processing plants, and we currently provide services to national customers such as Teys Australia, Thomas Foods International and Baiada Poultry.

Our senior programmer is an accredited Rockwell Authorised systems developer, available on a contract basis to the electrical contracting industry, and can provide expert assistance when a general contractor may wish to perform a contract that may ordinarily be outside their scope, and/or does not wish to employ a full-time programmer.

By utilising Rockwell Automation Logix technology we can offer a unique approach by using one control platform using a common control engine and development environment. Some of the many benefits and advantages gained by using this standardised approach to automating your plant include:

- One control engine with complete functionality.

- One development environment with complete functionality.

- Convergence of process, batch, discrete, drives, safety and motion into one automation discipline.

- Reduced development costs.

- Reduced maintenance and downtime costs.

- Reduced electrical design time.

- Reduced build time.

- Reduced installation time.

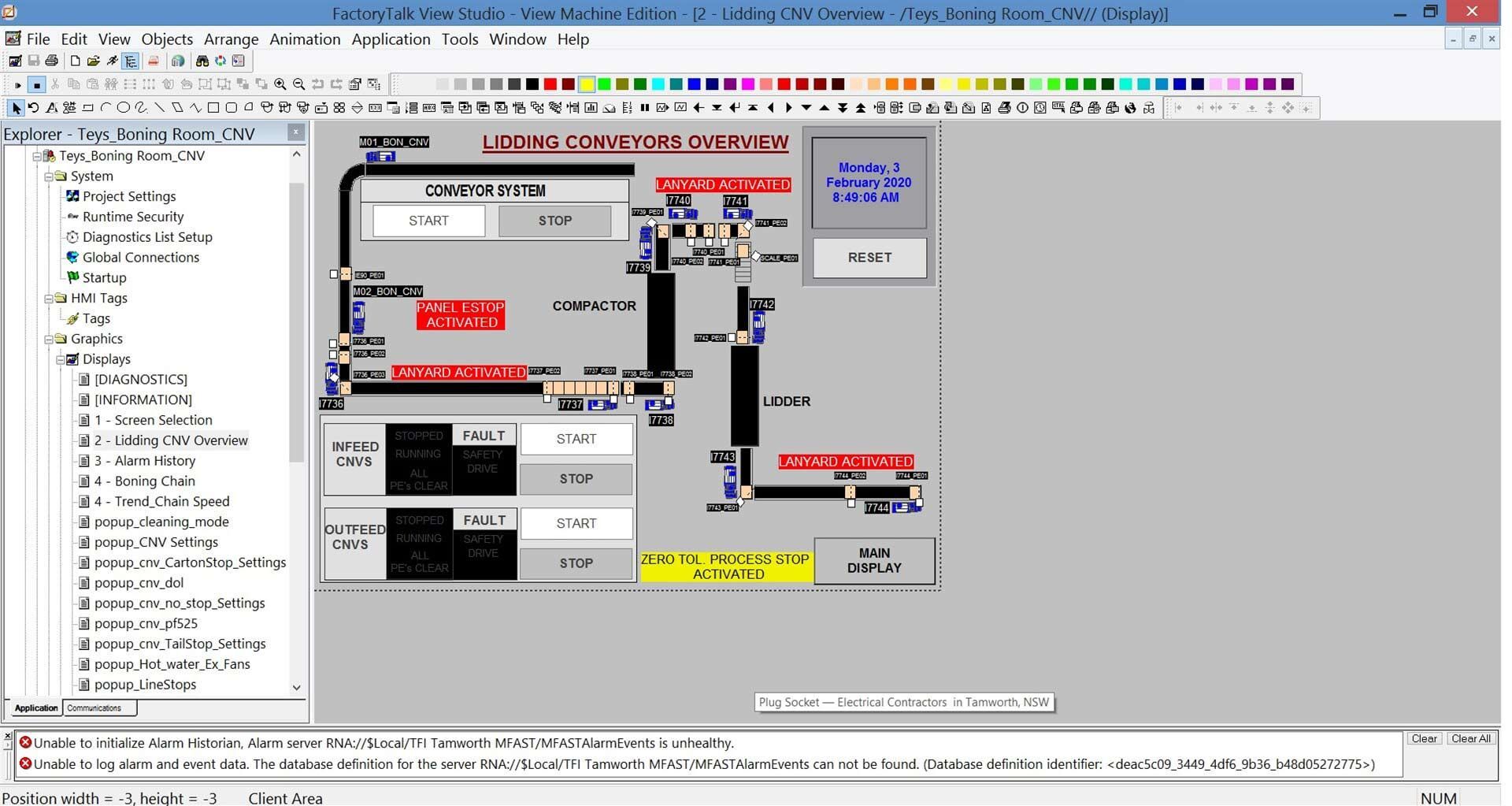

HMI/SCADA

As recognised Rockwell Automation systems developers (Allen Bradley) we have vast experience from FactoryTalk (RS) View (SE / ME), and we can undertake SCADA version upgrades and SCADA platform conversions. Our programming capabilities include the following products:

- RS View SE/ME

- RS View 32

- Panel Builder 32

- Wonderware

- Citect

- Panel View Plus HMI

- Panel View HMI

- VersaView Industrial Computers

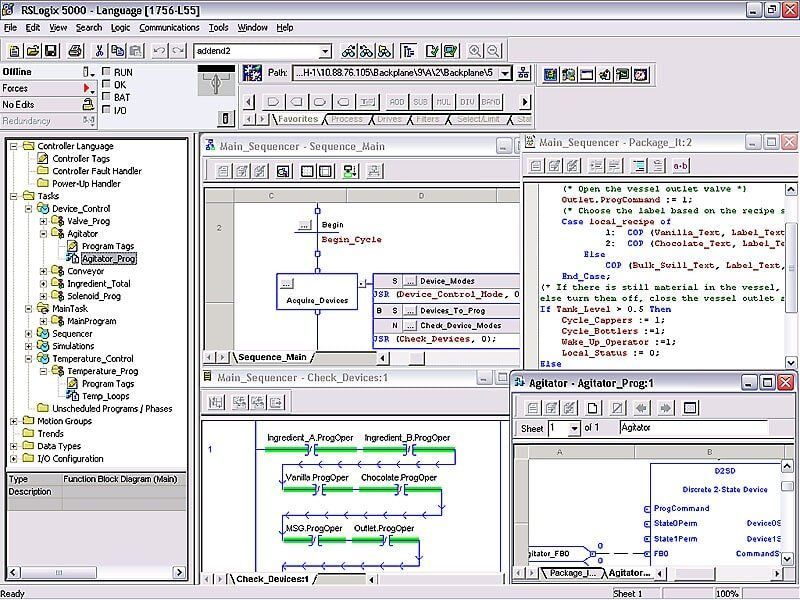

PLC Programming

As recognized Rockwell Automation systems developers (Allen Bradley) we have vast experience from microcontrollers to plant wide multi processor applications. We also offer PLC upgrading using specific migration software to minimise plant downtime and re-coding of existing programs, so that our clients can truly benefit from a new control platform with modern capabilities, reliability and features at reduced installation costs.

Our programming capabilities include the following products:

- Allen-Bradley - ControlLogix, CompactLogix, GuardLogix and MicroLogix

- GE Fanuc, Omron, Hitachi

- Pilz PSS Safety PLC

- PID Loop tuning and optimisation through software tools

- Communication Networks, Ethernet, DeviceNet and ControlNet

Enhancing Productivity with Plant Automation

Implementing plant automation in Tamworth offers a strategic advantage for businesses aiming to boost efficiency, reduce operational costs, and maintain consistent product quality. By integrating advanced control systems, companies can streamline processes, minimise human error, and respond swiftly to market demands.

Key benefits of plant automation include:

- Increased Efficiency: Automated systems operate continuously, enhancing production rates and reducing downtime.

- Improved Quality Control: Consistent processes produce uniform product quality, meeting stringent industry standards.

- Enhanced Safety: Automation reduces the need for manual intervention in hazardous environments, safeguarding workers.

- Data-Driven Decisions: Real-time monitoring and data collection facilitate informed decision-making and proactive maintenance.

Industries such as manufacturing, food processing, and wastewater management in Tamworth are increasingly adopting automation to stay competitive and meet evolving regulatory requirements.

For more information on plant automation solutions in Tamworth, feel free to

reach out to our team. We're here to help you enhance your operations through innovative automation technologies.